Page 1 of 2

standing rigging on C22...

Posted: Wed Feb 16, 2011 7:39 pm

by astrorad

I haven't inspected the standing rigging on my C22 yet, but I was wondering if anybody has replaced theirs? I really don't know if mine is original or not. I am kind of worried about rigging failure. I really do not have any idea about how much usage this boat has seen.

Posted: Wed Feb 16, 2011 8:55 pm

by Kevin Dreher

i am also concerned about my rigging..i dont thinks its original to the boat but not sure. i have some fraying on one of the smaller side stays on the mast. not sure if i can get by with replacing the one...or do i have to replace them all.......any info would be good info. thanks

kevin

Posted: Thu Feb 24, 2011 9:48 am

by skyking

I havnt replaced mine as of yet, but it is a good idea to put on some gloves at the begening of the season and run you hand down them looking for tell tale signs, ie fish hooks, etc.as well as inspecting all of the hardware...

I believe every 10 years is whats reccomended...

Posted: Thu Feb 24, 2011 11:04 am

by astrorad

I am not sure about this but I believe that it is pretty difficult to really be sure that your standing rigging is ok...I think that stainless can catastrophically fail without showing any outward signs due to hidden metal fatigue...anyone know more about this??

I suppose the prudent thing to do is invest the money ( $600-$800 probably) to have some piece of mind when you don't have a clue as to how old the rigging is or what kind of use that it has seen.

Posted: Thu Feb 24, 2011 12:50 pm

by Jmckamey

I had a complete set of standing rigging made for a Starboard Yachts Slipper 17 just about 6 years ago using 3/16 cable and it ran about $145.00. I was really surprised how good of a value it was. BTW, use a rag draped over the cable and save the skin.

Posted: Thu Feb 24, 2011 2:00 pm

by mcrandall

Hey Jim-

Was that stainless or galvanized?

Posted: Thu Feb 24, 2011 4:52 pm

by Windward

I've been replacing mine a bit at a time, starting with the headstay. Last I did were the aft lowers, which I ordered with aircraft fork swaged on the top and then cut to length and installed a Hayn HiMod fitting at the bottom. I also replaced the split bridle portion of the backstay. Next on the list are the uppers.

Biggest problem is not necessarily the wire, but the fittings. Crevice corrosion happens, and it's really hard to see flaws. I barely know enough to be dangerous, but have inspected the various forks with magnifying glass and bright lights. Haven't played with using dye yet.

None of my stays had any meathooks, although a couple did have some permanent bends. They straightened out fine under tension, but I sail Windward way too hard to take many hardware risks.

I am thinking that I'll check the old stays thoroughly, and may replace the fittings with more of the HiMods and use them to update the rigging on the Bristol. Not as good as new, but newer than what's installed and replacing what I perceive to be the most vulnerable components (the end fittings)

Posted: Thu Feb 24, 2011 7:09 pm

by astrorad

I am really impressed with Suncor Quick Attach fittings....I bought the life line kit from Bosun Supplies and the Suncor stuff looks very high quality.

It also is supposed to be stronger than swaged fittings.

Posted: Thu Feb 24, 2011 7:14 pm

by astrorad

The main reason I posted this thread is to see how many are using old or original rigging....I am trying not to replace more than I have to I guess...walking that line between $$$ and safety.

I do appreciate any and all feedback on this...I do tend to worry a bit.

Posted: Fri Feb 25, 2011 6:40 am

by John K

Posted: Fri Feb 25, 2011 7:16 am

by Jmckamey

SS

Posted: Fri Feb 25, 2011 7:22 am

by mcrandall

Thanks Jim!

Posted: Fri Feb 25, 2011 10:04 am

by back2class

on a trailer sailor that seems already over rigged i see no possible issue. if you race, see damage or push your boat very very hard that is another story. most of what you read is for boats that stay masted and have harder rigging lives than nearly any c22.

Posted: Fri Feb 25, 2011 10:18 am

by John K

I tend to agree with you. Periodic inspections go a long way. I think making sure that you haven't lost a little retaining clip here or there is probably the most pressing issue, especially in a fresh water environment. There are thousands of Catalina 22's out there with rigging that feels like dental floss in comparison, and I've never heard of a rigging failure on one.

Posted: Sun Feb 27, 2011 7:28 am

by astrorad

thanx for all the great input.....I am going to do a thorough inspection of my rigging with magnifying light and with the dye method I have previously posted...then I will see what it all looks like when I eventually set up mast for the first time in my driveway this summer.....

Posted: Sun Feb 27, 2011 8:00 am

by mcrandall

Bill-

What is the dye method that you speak of? Can you repost?

Thanks!

Mark

Posted: Sun Feb 27, 2011 5:22 pm

by astrorad

Mark,

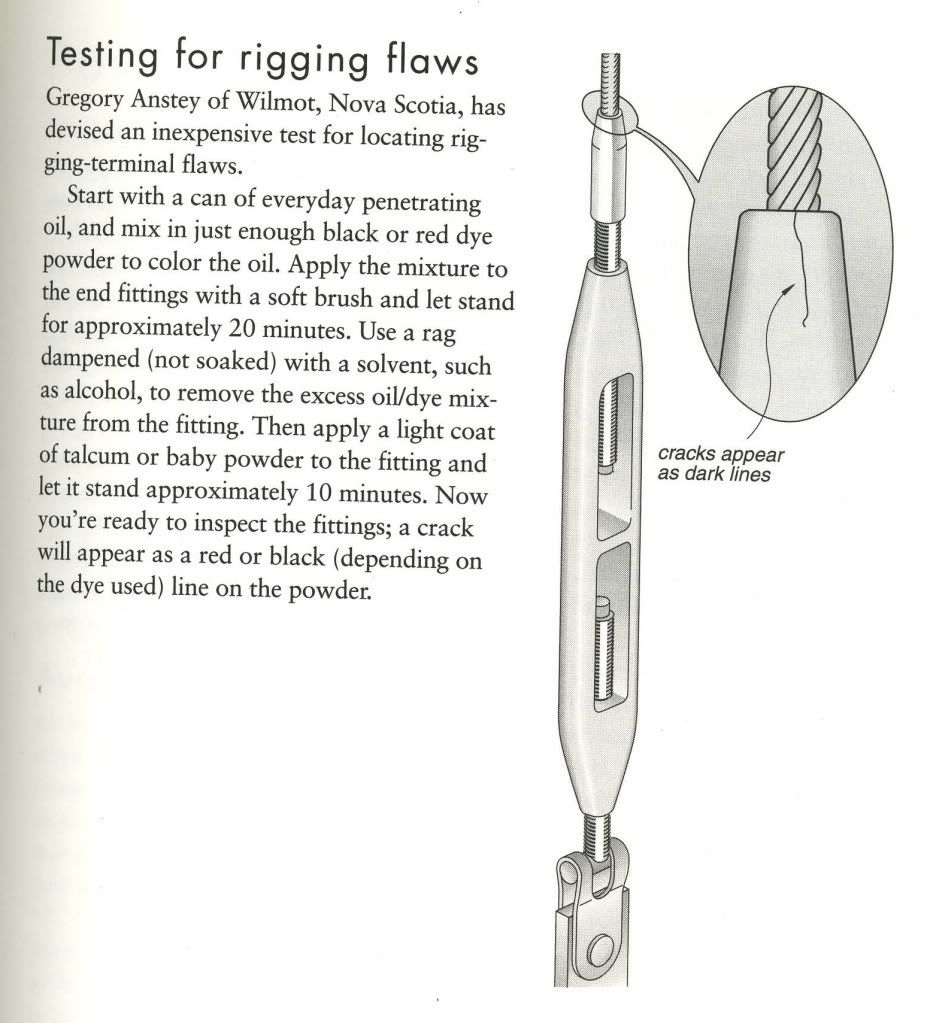

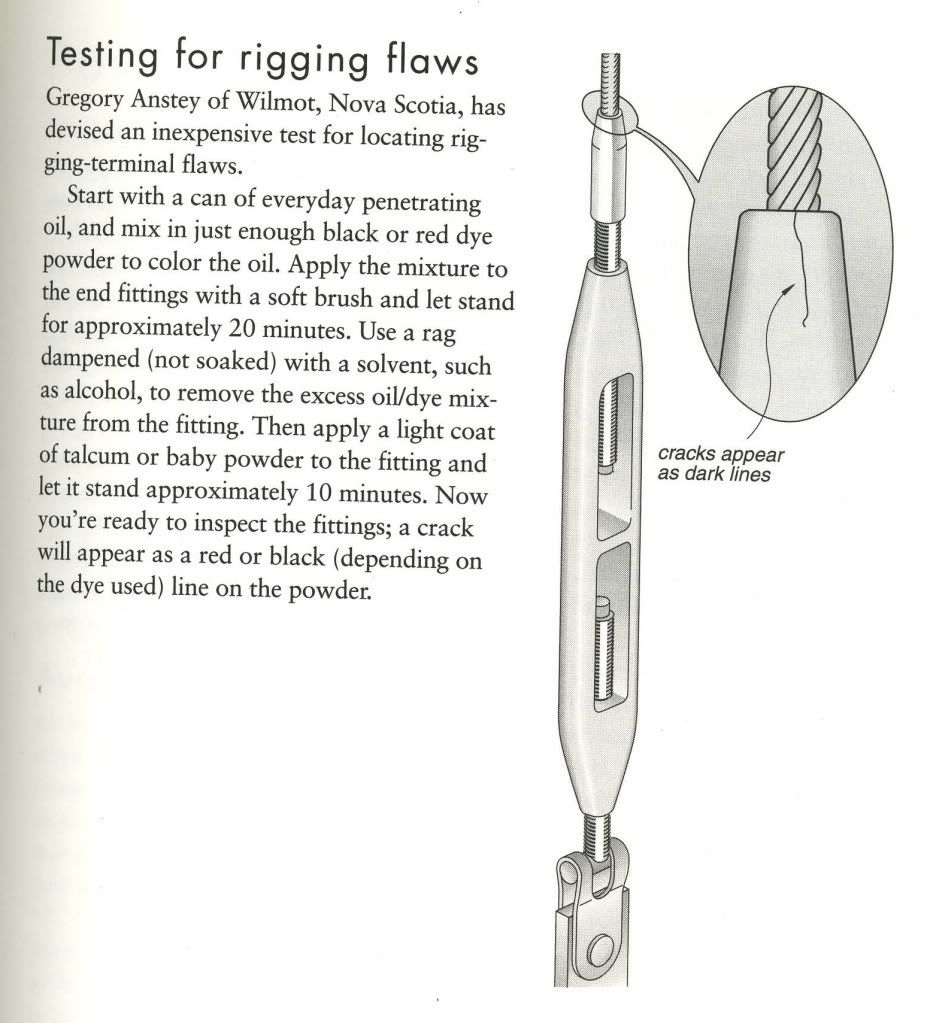

I got this from a book called "The Best of Sail Magazine's Things That Work".

Haven't tried it yet but sounds logical....

Posted: Sun Feb 27, 2011 5:54 pm

by mcrandall

Looks interesting, I'll give it a try too. Thanks Bill!

Posted: Sun Feb 27, 2011 6:24 pm

by skyking

LIQUIED DYE PENETRANT INSPECTION > SPOTCHECK

This method is widley used in the welding industry, used the same as described above.

simply clean the area that you want to test for cracks...spray on some dye, wait a few minutes, then spray your cleaner on a rag and wipe off the dye, let dry and spray on the developer...if there is the slightest crack it will bleed .

Be sure not to spray cleaner onto the surface being tested once you have applied the dye...you dont want to wash it out of any cracks resulting in a false reading..wipe it off with a rag.

I have attached a link, but you should be able to get these items at any welding supply shop

LIQUIED DYE PENETRANT INSPECTION > SPOTCHECK

SKL-4C Water Based Penetrant

SKD-S2 Non-Chlorinated Developer

SKC-S Non-Chlorinated Cleaner/Remover

http://www.ndtsupplies.com/spma.html

Posted: Mon Feb 28, 2011 9:40 am

by Capt. Bondo

OH NO

Now I have a reason to visit the welding supply store

Who knows what cool, neet things I'll find in there that I'll want to buy

Posted: Mon Feb 28, 2011 10:38 am

by mcrandall

No kidding, Capt B!!!

My wallet HATES walking into that place!

Posted: Thu Jul 28, 2011 10:04 am

by mariner

Can anyone recommend an online rigging store that they were happy with? there is a rigger here in town that i met with he knows his stuff but he is using old/salvaged hardware, just don't have a comfort level yet... not sure what to do...

New rigging

Posted: Fri Aug 19, 2011 3:10 pm

by mariner

Well I finally bit the bullet and ordered all new standing rigging, it started with just some (there was some unwinding and failure) and then from talking to a few people I guessed that it would be a good investment to replace 35 year old rigging... I eventually went with Seco South, very friendly and I cannot believe the price, I paid 350 bucks for all of the rigging including new turnbuckles, they even sent me some new line and a package of cotter pins! Hats off to Jean at Secosouth

New un-boxing!

Old Adjusters

New Ends

http://www.secosouth.com/mm5/merchant.m ... _Code=SECO

Posted: Fri Aug 19, 2011 4:18 pm

by monty

oooh! shiny! nice!!

been wondering about mine too. I've got some broken strands right at the edge of one of the swaged forks on a lower stay. I look up at it after each gust . . . hoping it's still holding!!

has anyone ever had rigging fail? I've never had it happen personally, but have seen it on others, funny though, only to people that are real careless when rigging, ie, twists in the stays as they raise the mast!!

Posted: Sun Aug 21, 2011 3:13 pm

by thepartydog

Big brother had the rigging inspected by a pro rigger in Kemah before we left, $150 ish for the inspection.

Posted: Fri Aug 26, 2011 4:10 pm

by trev

Mariner,

Can you tell me the pin size of the fork for the back stay? looks like it is different for the single wire and the split wires.

Thanks

Posted: Sat Aug 27, 2011 5:10 am

by mariner

trev wrote:Mariner,

Can you tell me the pin size of the fork for the back stay? looks like it is different for the single wire and the split wires.

Thanks

on my setup (I believe that it is OEM) all of the aircraft forks are the same size (5) the cotter pin hole diam is 1/4", the pin is slightly smaller.

the photos below are from the OEM.

The back stay had a rigging adjuster, the new ones I had made now have a turnbuckle. (rigging adjusters are a pain to adjust)

Posted: Sat Aug 27, 2011 6:13 pm

by astrorad

Hey Mariner...how is the backstay setup now in the new rigging? One turnbuckle in the main cable above the split or one or two turnbuckles in the wires below the split? What was your method for measuring your old rigging?

I really think I will order from Seco also if you think that the quality is good.

I will definitely be more comfortable with all new standing rigging.

Posted: Sat Aug 27, 2011 6:32 pm

by mariner

Bill, I have one turnbuckle a I've the split. Secosouth instructed me to send all of the rigging in just like I took it off of the boat, they did the measure from there. I guess thats how they ensure the fit. The quality is very good from what I can see, and the price can not be beat. From talking to them, they are the oem provider fir rigging for several manufacturers and have been around for a long time. I'm planning on having them build my lifelines as soon as I'm ready.

Tony

Posted: Sat Aug 27, 2011 6:36 pm

by astrorad

Thanks Tony...Did they send the old rigging back...mine is all pretty good looking so would be nice to have it for spare just in case.